Materials you trust

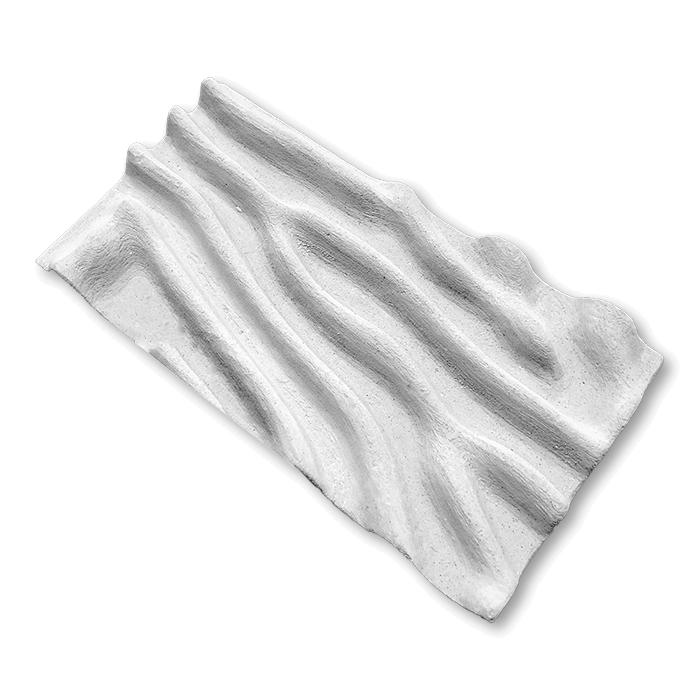

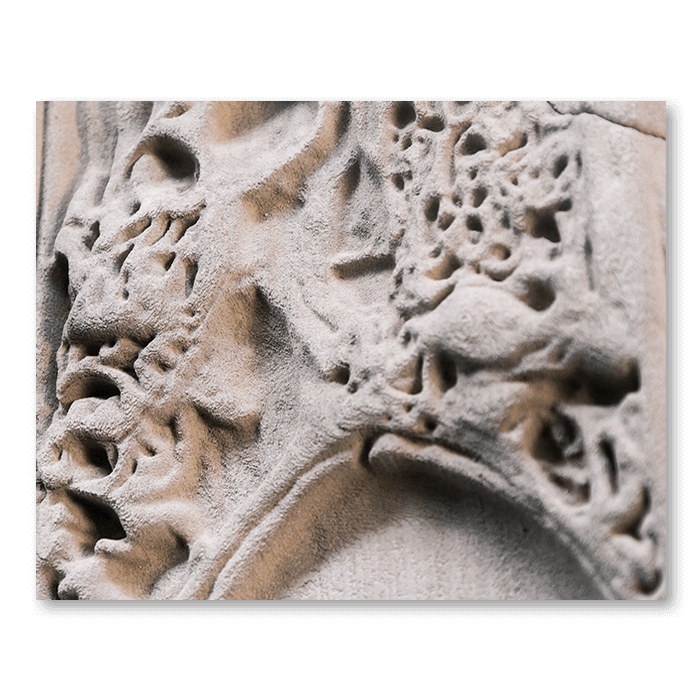

Our binder jetting platform allows you to 3D print complex forms in materials such as limestone, granite, and marble. Thanks to excellent material properties and the ability to seal printed objects for outdoor use, your customers can literally build on the products leaving your production facility.

Exceptional scalability

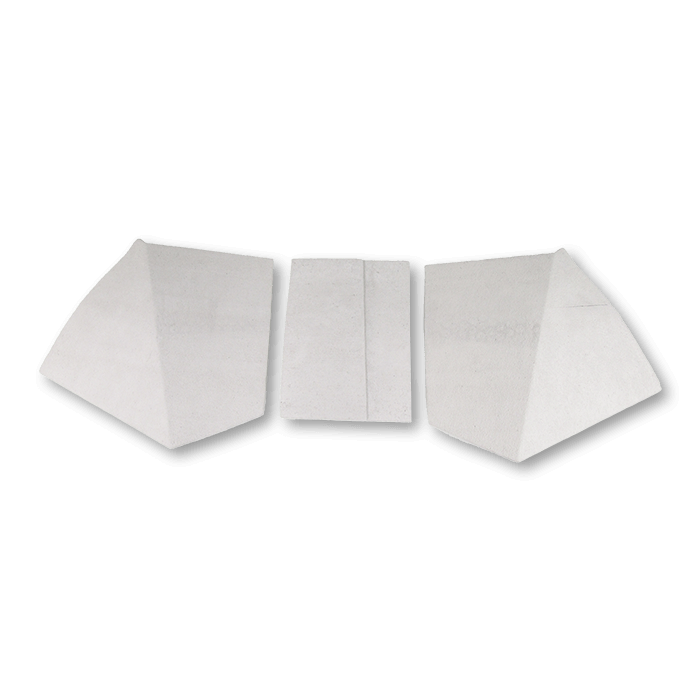

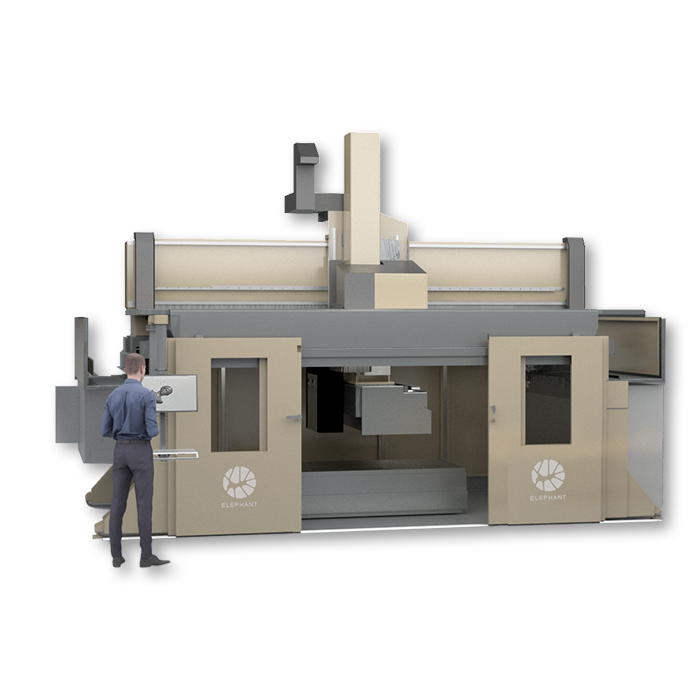

CONCR3DE gives you an easy path from small-scale prototyping to large-scale manufacturing. Test designs, finishes and materials on our Armadillo platform and when you’re ready, scale up to one of our large-scale printers, which allow you to print objects of up to 6 x 3 x 1 meters in size. All printers use the same base technology, meaning you don’t have to reinvent the wheel.

Sustainable manufacturing

Our platform enables true upcycling - using waste streams to create new objects. Materials like stone sawdust and filter cake, or even minerals retrieved from urban mining processes can be used as printing materials. Combined with the raw materials reduction and our zero-waste production process, we can significantly reduce the amount of waste in large-scale manufacturing together.