Ceramics & Metals

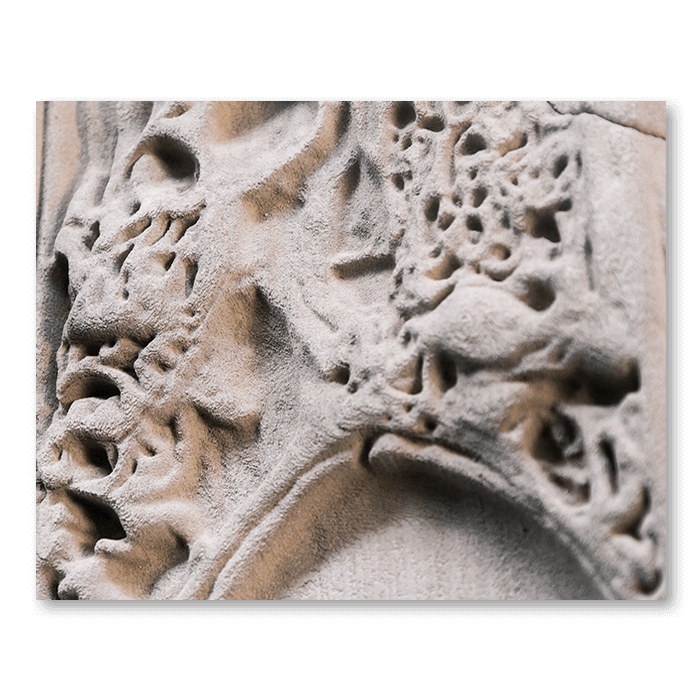

Our accessible technology enables researchers to test and develop metal and ceramics material options. This results in the certified material options being rapidly expanded – for example with a range of high-tech applications as well as sustainable options.

Technology

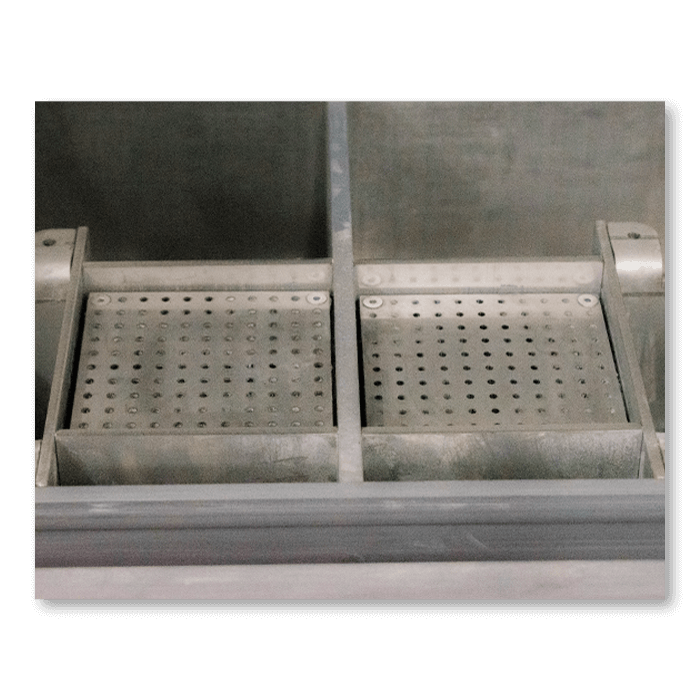

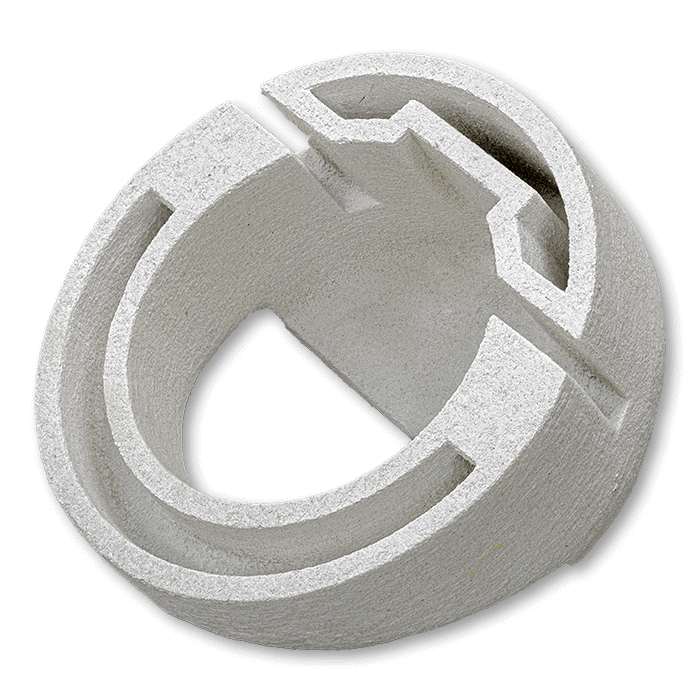

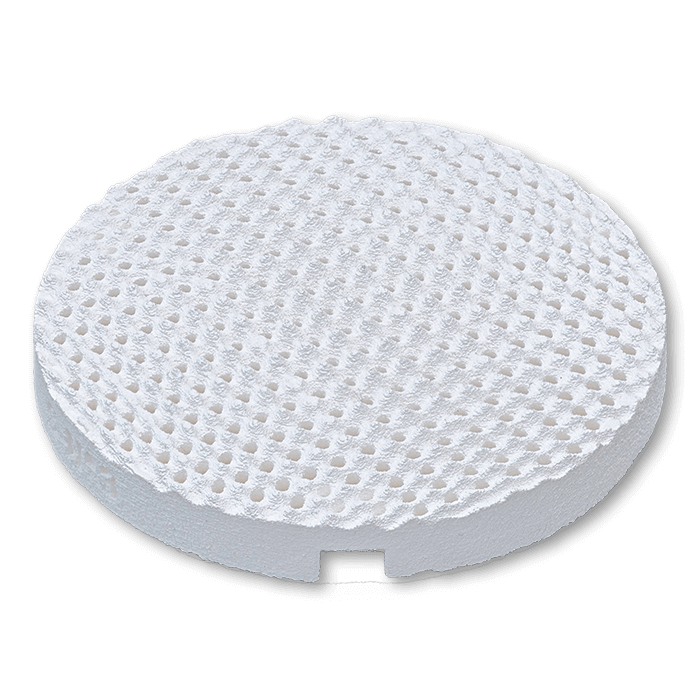

Binder jetting 3D printing is based on two key elements: a powder and a binder. The powder can be a concrete, metal, ceramic, or other material you want to bond in powder form. The binder is a liquid, which acts as an adhesive between powder layers.